Liquid Phase Peptide Synthesis (LPPS): Cases & Strategic Advantages-CongenPharma-Patented Technology

Publish Time:

2025-08-07

Liquid Phase Peptide Synthesis (LPPS): Cases & Strategic Advantages-CongenPharma-Patented Technology

Liquid Phase Peptide Synthesis (LPPS) is a classical method for assembling peptides in solution, predating the now-dominant Solid Phase Peptide Synthesis (SPPS). Though often considered less convenient than SPPS, LPPS remains a valuable tool, particularly in industrial-scale synthesis and certain high-purity applications.

1. Methods of Liquid Phase Peptide Synthesis

1.1 Stepwise Synthesis

- Description: Amino acids are sequentially coupled in solution using protecting groups (e.g., Boc, Fmoc) to prevent side reactions.

- Common Coupling Reagents: DCC, DIC, HOBt, HATU.

- Solvents: DCM, DMF, THF, MeOH depending on solubility and reaction stage.

1.2 Fragment Condensation

- Description: Larger peptide segments (di-, tri-, or tetrapeptides) are synthesized separately and then coupled.

- Advantage: Reduces the number of steps, potentially improving yield and purity.

1.3 Protecting Group Strategies

- N-terminal: Boc (acid-labile), Fmoc (base-labile).

- Side Chains: t-butyl, benzyl groups for selective protection.

1.4 Purification Techniques

- Liquid-liquid extraction

- Crystallization

- Recrystallization of intermediates

- Column chromatography (limited in large-scale LPPS)

2. Use Cases for LPPS

2.1 Industrial-Scale Peptide Production

- Especially effective when large batches of short-to-medium-length peptides are needed.

- Cost-effective due to the ability to recycle solvents and reagents.

2.2 Synthesis of Difficult Sequences

- Useful for peptides that are poorly soluble on solid supports.

- Better control over reaction conditions (e.g., concentration, temperature).

2.3 Fragment-Based Synthesis

- Efficient for long peptides via convergent assembly of fragments.

- Reduces cumulative yield loss over lengthy sequences.

2.4 Cyclic Peptides and Peptidomimetics

- Offers more flexibility in cyclization strategies and solvent manipulation.

3. Strategic Advantages of LPPS

3.1 High Purity Potential

- Crystalline intermediates allow for purification at each step.

- Reduced resin-derived impurities compared to SPPS.

3.2 Scalability

- Well-suited for multigram to kilogram synthesis.

- Cost per unit can be lower when scaled due to solvent reusability.

3.3 Enhanced Process Control

- Allows fine-tuning of reaction parameters that are difficult to optimize on solid supports.

3.4 Minimal Resin Costs

- Eliminates expensive resin procurement and disposal issues.

4. LPPS vs SPPS: Comparison

| Feature | LPPS | SPPS |

| Purification | Intermediate crystallization | Crude product at end |

| Automation | Less suitable | Highly automatable |

| Scale-Up | Easier (solution-based) | Limited by resin loading capacity |

| Speed | Slower | Faster cycles |

| Cost (large-scale) | Often lower | Higher due to resin/reagent waste |

5. Challenges & Considerations

- Time-Intensive: Each step requires purification and drying.

- Solubility Issues: Some intermediates can precipitate prematurely.

- Requires Skilled Handling: More manual labor and analytical control.

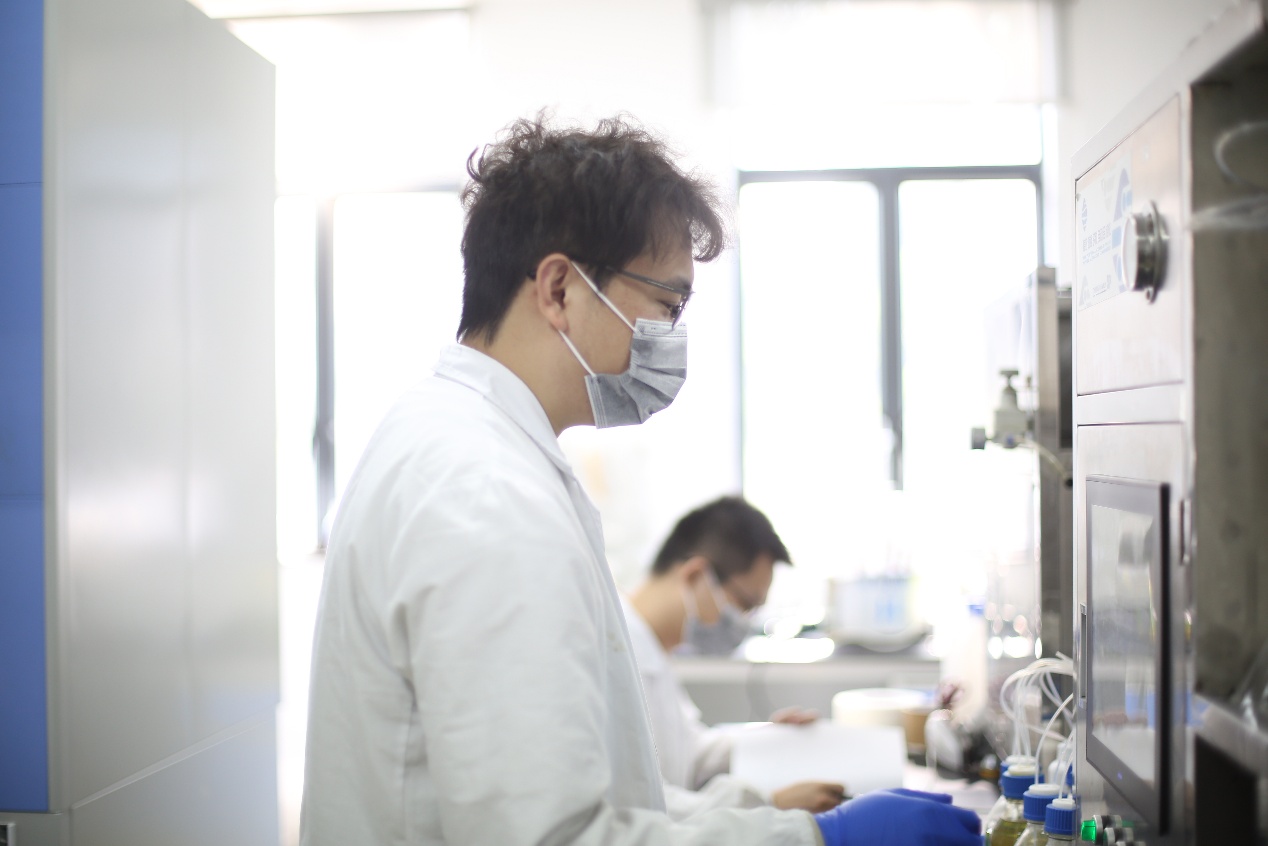

Of course, we have a professional team and experienced specialists with sophisticated skills to solve these challenges.

Liquid Phase Peptide Synthesis (LPPS)

Strategic Advantages & Application Use Cases

Advantages of Liquid Phase Peptide Synthesis (LPPS)

High Purity & Stepwise Control

Each intermediate is purified after coupling, allowing by-products to be removed early. This ensures higher

crude purity compared to SPPS and maintains sequence fidelity—especially valuable in regulated

environments.

Better Suited for Complex or Long Sequences

By leveraging fragment coupling, LPPS allows the synthesis and purification of shorter segments before

linking. This enables production of long or structurally challenging sequences.

Scalable for Short Peptides

Ideal for commercial-scale production of short peptides. LPPS eliminates resin costs and solvent swelling

issues, supporting cost-effective manufacturing for generics or cosmetic peptides.

Greater Chemical Flexibility

LPPS provides fine control over solvents, reagents, and conditions—beneficial for incorporating unusual

amino acids, forming disulfide bonds, and performing PEGylation or cyclization.

High Yield for Short Chains

Accurate stoichiometry and stepwise purification allow excellent yields for short sequences, making LPPS

ideal for dipeptides, tripeptides, and other low-molecular-weight peptides.

Use Cases & Applications

Bulk Production of Simple Peptides

For small peptides used in cosmetics, nutraceuticals, or intermediates—such as dipeptides or

tripeptides—LPPS enables cost-efficient large-scale production. Its compatibility with crystallization and

batch processes makes it ideal for commercial output.

Why Choose Our Peptide Synthesis Services?

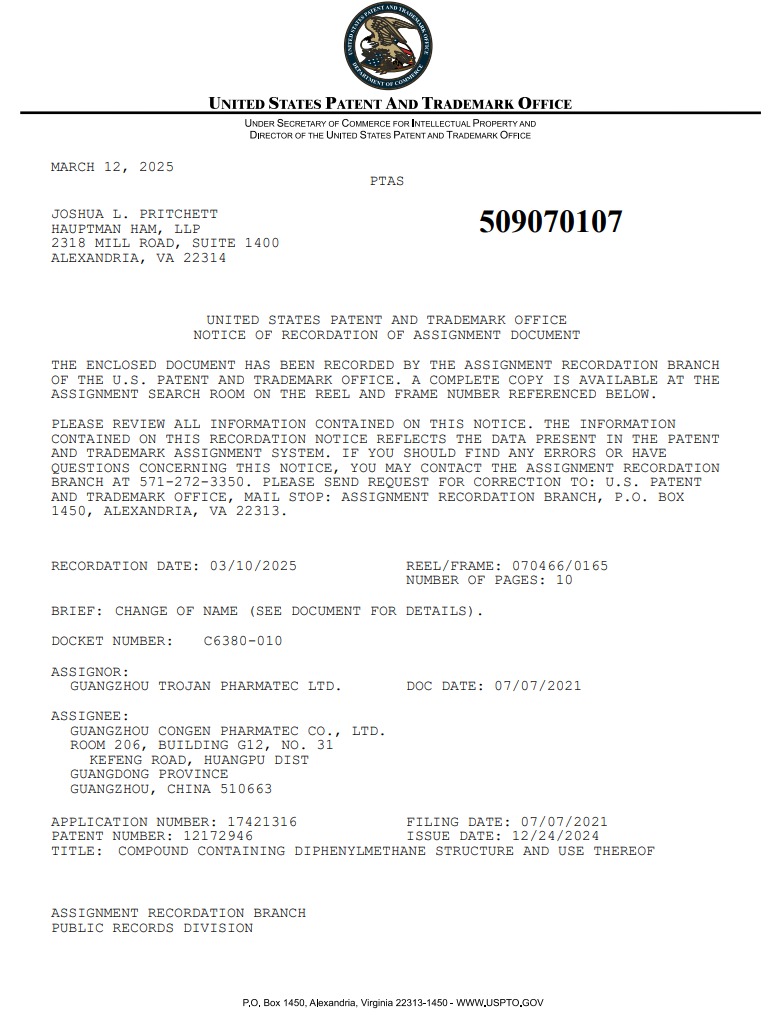

Our proprietary Liquid Phase Peptide Synthesis (LPPS) technology, developed by CongenPharma is protected by a U.S. patent. Compared to traditional liquid-phase methods, our process is greener, more sustainable, and scalable for industrial production. It significantly reduces production costs and shortens the synthesis cycle by one-third.

Prev:

Relevant Information

undefined